Increased production demands have resulted in faster, wider, more heavily loaded conveyor belts, resulting in increased carryback. Carryback under the belt and on structures increases replacement, maintenance, clean-up costs and OH&S risks.

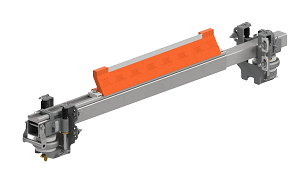

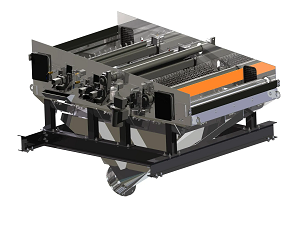

The ESS Inline XHD Secondary Cleaners aim to deliver superior belt cleaning performance for heavy-duty applications where larger, more durable belt cleaners and longer time between blade change-outs are required.

Features and Benefits

Mainframe & Cartridge

The ESS Inline XHD Secondary Cleaners use a mainframe and cartridge manufactured from mild or stainless steel, making them suitable for all environments, including sites that deal with corrosive material. The robust frame utilises a mandrel mount to reduce blade change-out times by allowing for a retractable track so that blades can be changed out from one side. The Inline XHD, like the XHD Primary, is designed to enable the track to be unbolted for further ease of blade change.

Tensioning Bracket

The Inline XHD tensioning bracket design utilises two stainless steel rods for the slide bracket to move up and down. This new design offers the benefit of creating a belt cleaner that is more reactive to belt movement while maintaining the optimal angle for efficient belt cleaning.

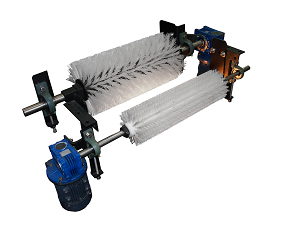

Tensioning Devices

The Tensioning devices maintain blade-to-belt pressure throughout the blade's life with minimal adjustment. This provides optimal cleaning performance while preserving blade wear rates and removing material that would otherwise pass between the belt and the blade surface.

The Inline XHD cleaner offers two tensioning units: spring and air. The Air tensioner utilises the same airbags as the IPS and Inline Premium Air Tensioners. The Spring tensioner unit has been designed with a robust spring to support the heavier hard wear and load pressure.

Blades

ESS' modular blades allow for optimal blade-to-belt contact, with blade change-out being a quick and simple process. This minimises site downtime and reduces manual handling risks during installation and maintenance.

The Inline XHD Cleaner blades are three times bigger than the standard blade, meaning longer wear and less frequent blade change-outs.

The Inline XHD Cleaner offers various modular blades that can be changed to suit the surface conditions throughout the entire belt's entire life. Tungsten Carbide Blades (For very abrasive materials and high-speed belts. Also suitable for mechanically spliced belts ), Urethane Blades (for damaged belts and special applications) and reversing blades. ESS offers segmented blades, allowing easy removal even with the accumulation of material on the cleaner.

Related Products

Contact our team to enquire more about our belt cleaners