Precision cleaning with minimal wear and tear on the belt. Designed for small spaces.

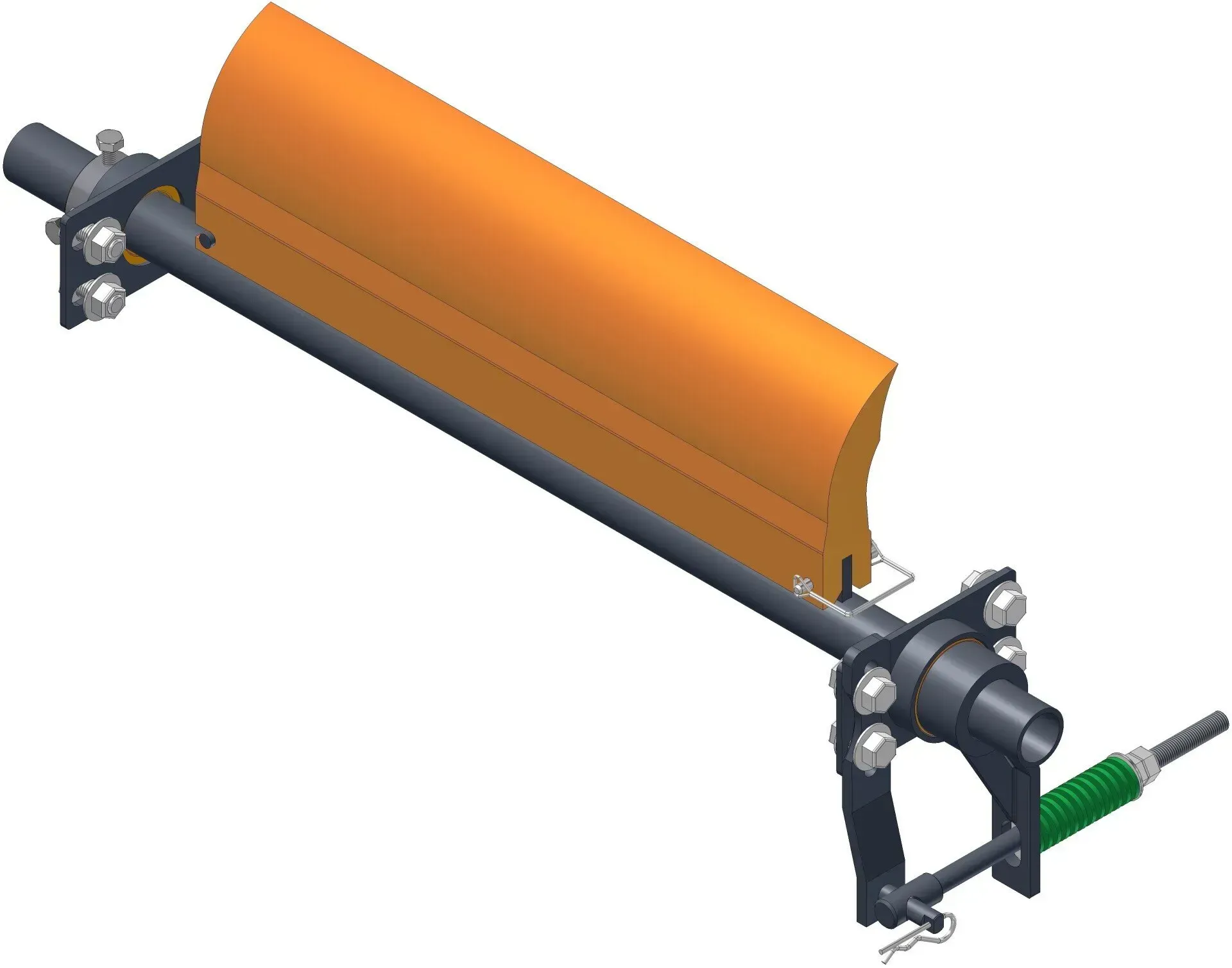

The TM Doctor Blade Primary cleaner is suitable for small spaces. It has a flexible configuration and choice of blade types and tensioning devices. The modular blade is designed to allow for blade wear compensation and reduce manual handling

Features and Benefits

Mainframe

The mainframe is available in either mild steel or stainless steel constructions, which means that corrosive environments can be catered to.

Tensioning Devices

There are several typed of tensioning device available to maintain the blade to belt pressure throughout the life of the blade. This provides optimal cleaning performance while preserving blade wear rates removing material that would otherwise pass between the belt and the blade surface. Differing styles of tensioning device are and can be customised to suit what is available at each plant. ESS tensioning device allows blade adjustment while the conveyor is still running from outside the chute, allowing the applied pressure to be fine-tuning without the need to stop production.

Blade Type

Modular blade design provides increased wear life and ability to change blade order or material. Constant Angle, Radial Pressure (CARP) blade profile assures that there is a consistent even blade to belt contact throughout the life of the blade. This provides efficient and protective cleaning. A variety of urethane types allow blades to conform to the belt profile and conditions.

Urethane

Urethane blade material protects the belt surface and splices from damage and is designed to fold back and pull through rather than damage the conveyor belts surface or splices if the belt reverses or experiences rollback. The risk of conveyor belt damage or replacement and subsequent downtime to repair or replace is effectively reduced.

Related Products

Contact our team to enquire more about our primary belt cleaners