Cleans the belt at a negative angle while reducing damage to the belt caused by splices and other irregularities on high-speed belts.

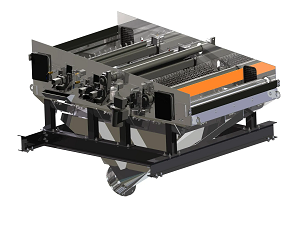

Conveyor belt carryback is a common issue that can lead to decreased efficiency, safety hazards, increased maintenance costs, and environmental pollution. Scheduled maintenance shutdowns of the conveyor belts are necessary to ensure smooth and efficient bulk handling. During these shutdowns, performing blade change-outs swiftly and safely minimises production downtime and maintains optimal cleaning efficiency.

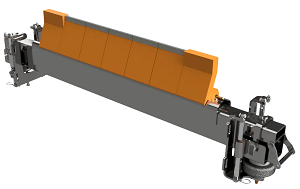

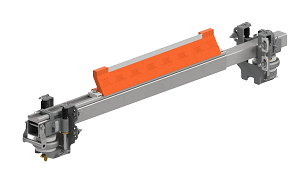

The DT Torsion Arm Secondary Belt Cleaner effectively cleans the belt at a negative angle, absorbing the impact of splices and other irregularities on high-speed belts and reducing damage to the belt.

Features and Benefits

Blades

ESS offers a range of blade materials that include: urethanes, plastics, abrasion resistant tool steel and tungsten carbide which can be customised to suit the type of material and the condition of the belt. This allows optimal cleaning without damaging the conveyor belt surface of splices.

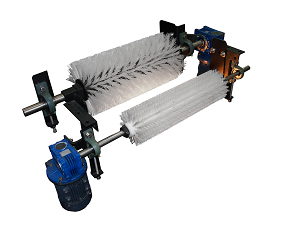

The blades overlap to provide total coverage of the belt. These blades snap in and out of the urethane arms with a swivel action that allows deflection from faults in the belt surface before any damage is done. This also means that blade change-out can be done quickly by one technician as there are no nuts and bolts, so service time is significantly reduced.

The urethane support arms are available in a range of urethane types which allows the arms to move independently while retaining the correct blade to belt tension. These arms are modular in design and are removed for service along the mainframe track, resulting in reduced service times and personnel.

Mainframe

The mainframe is a simple, robust construction made from a polyethene sleeve and telescoping ends in mild or stainless steel. The blade assemblies slide along the track without the need for fasteners. This allows for easy replacement even after working in sever, dirty or corrosive conditions. The mainframe is available in mild steel, polymer steel or stainless steel constructions; this means that corrosive environments can be catered for. The mainframe can be customised to suit conveyor stringer arrangements.

Tensioning Devices

There are several types of tensioning devices available to maintain the blade to belt pressure throughout the life of the blade. This provides optimal cleaning performance while preserving blade wear rates removing material that would otherwise pass between the belt and the blade surface.

Related Products

Contact our team to enquire more about our belt cleaners