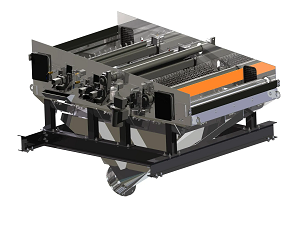

Designed to remove any material sticking to the belt's return side, working with a Primary and Secondary Cleaner.

Carryback from conveyor belts is an everyday occurrence, resulting in reduced operation efficiency, safety, maintenance costs, and environmental contamination. In some applications, the material is fine and dry, and as it moves along the conveyor belt, it creates a static charge, allowing the fugitive material to cling to the underside of the belt. Because the material is so fine, removing it with blade cleaners is difficult.

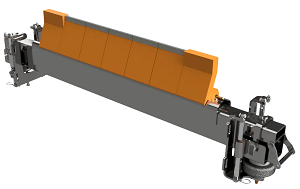

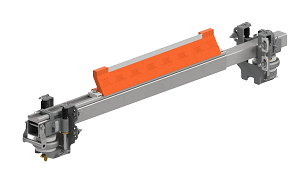

The ESS Static Brush Cleaner is designed to remove adhering material from the return side of the belt in conjunction with a

Primary and

Secondary Belt Cleaner. The ESS Static Brush Cleaner is suitable for light to medium applications, running on belts that run up to 2 meters per second.

Features and Benefits

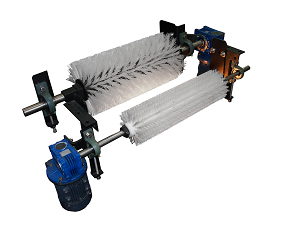

Brush Units

The brush is available as a single or dual unit. Its bristles are made of nylon as a standard, but other materials can be easily sourced if you have different requirements.

The Brush element is held in an easily removable cartridge, which means that there are typically no confined space issues when replacing the brush.

The Static Brush Cleaner is suitable for removing fine and dry powdery materials with a static charge, which are difficult to scrape off the belt. Such materials include alumina, cement and fine sands.

Tensioner

The Jack Screw Tensioner maintains brush-to-belt pressure with a minimal amount of maintenance. This provides optimal cleaning performance while preserving brush wear rates and removing material that would otherwise pass between the belt and brush surface.

Mainframe

The ESS Static Brush Cleaner mainframe is available in stainless steel for robust construction. The ESS Static Brush Cleaner is available for a range of conveyors between 450-2400mm wide. The ESS Static Brush cleaner is non-directional, making it suitable for reversing belts.

Related Products

Contact our team to enquire more about our belt cleaners