Secondary Belt Cleaners

Delivering Conveyor Productivity Improvements

Exceptional performance and low maintenance requirements, resulting in increased productivity and decreased maintenance expenses.

Secondary conveyor belt cleaners are essential components in material handling systems, designed to remove residual material that remains after the primary cleaning process. They are installed behind the drive pulley and ensure that excess debris does not adhere to the belt and cause issues like belt misalignment, increased wear, and operational inefficiency.

By optimising the belt's cleanliness, these cleaners significantly extend the lifespan of the conveyor belt and reduce maintenance costs. They use tensioned blades or brushes that are adjusted to make close contact with the belt, scraping off material that the primary cleaner couldn't remove. This enhances the efficiency and longevity of the conveyor system, making secondary belt cleaners a worthwhile investment for any operation that relies on conveyor belts.

SECONDARY Belt Cleaners Range

Our lineup includes the Standard Inline Secondary for general applications, the IPS Secondary for high-impact conditions, and the XHD Inline Secondary for extreme-duty scenarios. Consider our DH Secondary, Rotary Brush Secondary, and Static Brush Secondary cleaners for specialised needs. The DT Torsion Arm Secondary offers versatile performance, while our Wash Station provides an integrated cleaning solution. Upgrade your conveyor system with the top-quality secondary belt cleaners from ESS Engineering.

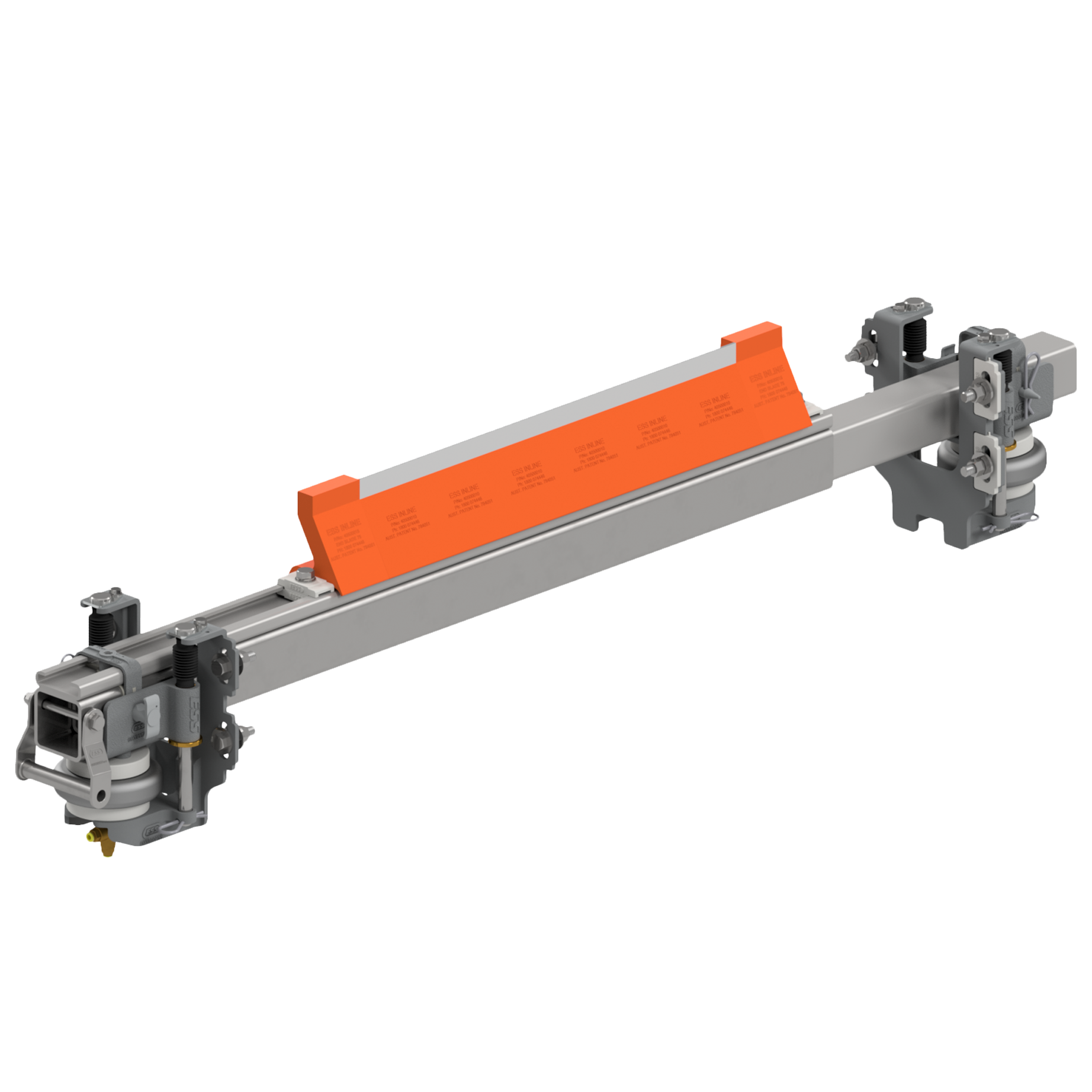

STANDARD INLINE SECONDARY

The Inline Standard Secondary Cleaner is normally mounted so the cleaning blades contact the belt as it leaves the head pulley or other accessible position on the return belt.

The blades of the ESS Engineering Services & Supplies’ Inline Standard Belt Cleaner, when tensioned, lie in the direction of belt travel, giving a negative angle and presenting no snag or danger to the belt or splices.

IPS SECONDARY

The IPS is an upgraded version of the ESS InLine 20-Ten Premium Cleaner & the original ESS InLine cleaner, which set the standard for cleaning performance combined with safety and ease of servicing.

XHD INLINE SECONDARY

The IPS is an upgraded version of the ESS InLine 20-Ten Premium Cleaner & the original ESS InLine cleaner, which set the ESS XHD Inline cleaner is a heavy-duty version of the ESS IPS cleaner.

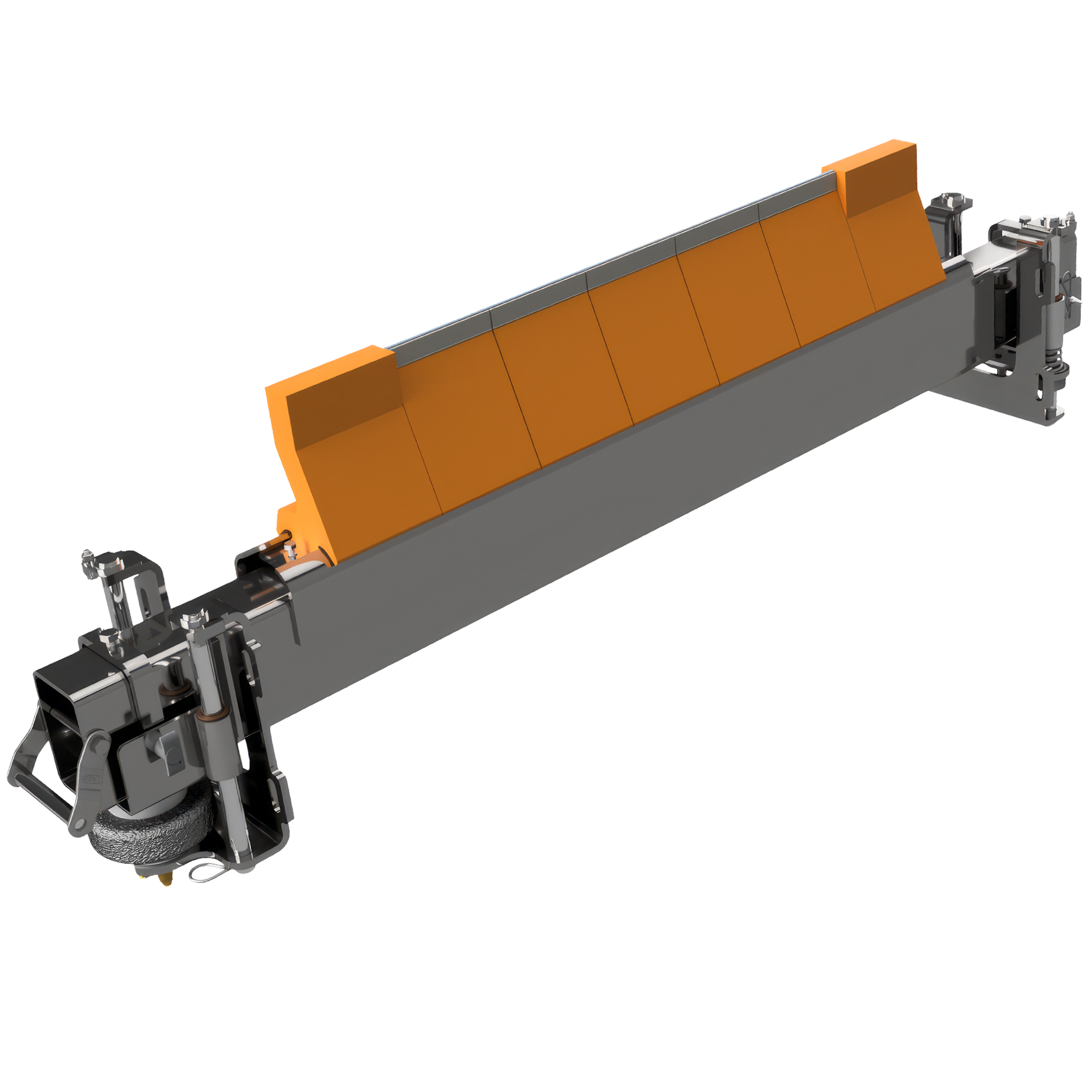

DT TORSION ARM SECONDARY

The DT Torsion Arm is normally mounted under the head pulley or elsewhere on the return strand of the conveyor belt. The blades of the DT Torsion Arm meet the belt at a negative angle, presenting reduced danger to the belt or splices.

The blades are set at a scraping angle to the belt, providing precise cleaning while cleaner arms absorb the impact of splices or other irregularities of high-speed belts.

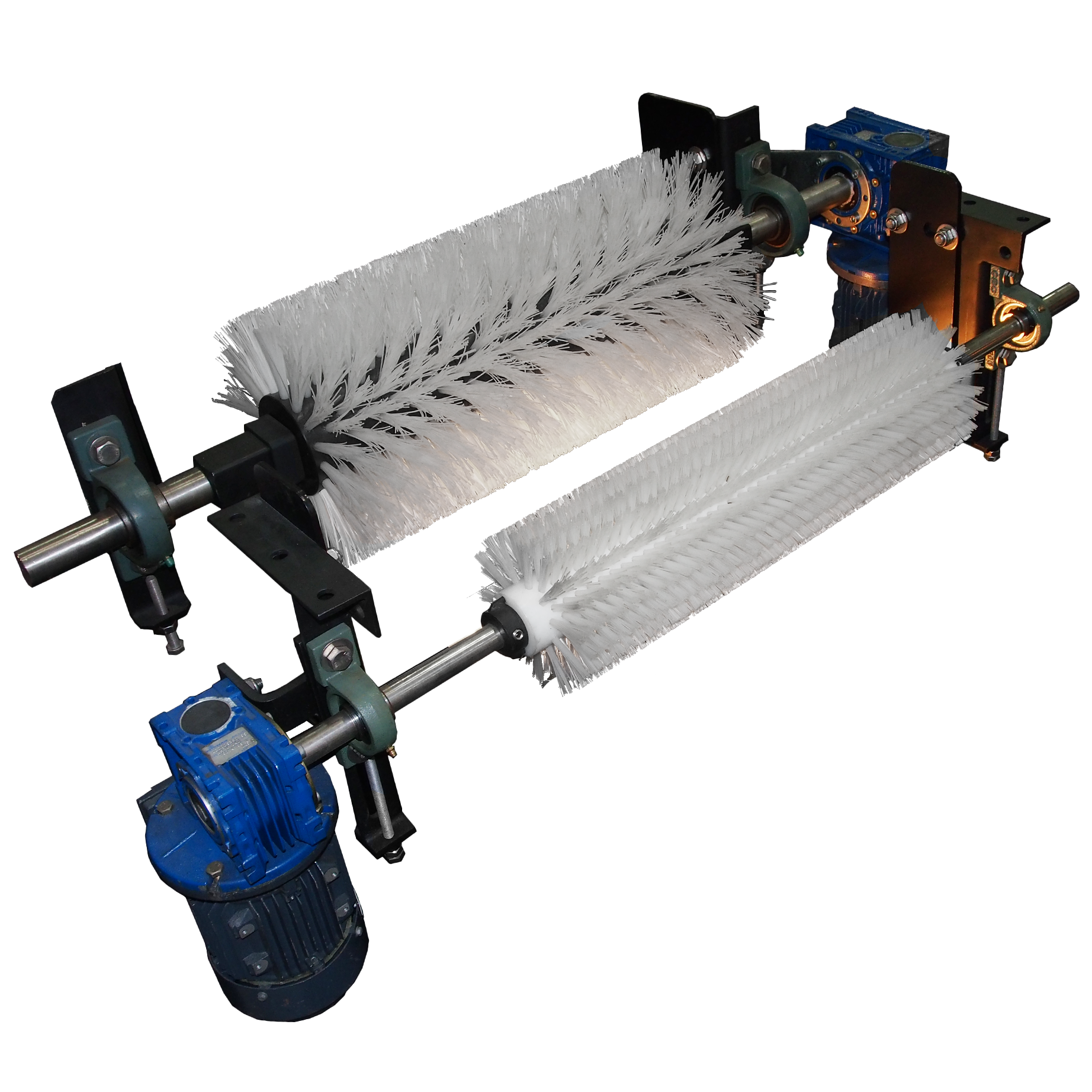

ROTARY BRUSH SECONDARY

The ESS Brush Cleaner is a motorised rotary brush designed to remove adhering material from the return side of conveyor belts.

The ESS Brush Cleaner removes dry fibres and fines from the belt.

STATIC BRUSH SECONDARY

The Static Brush Conveyor Belt Cleaner should be used following a standard belt cleaning system comprising of a primary cleaner, which will remove the bulk of the adhering carry-back and prevents the static brush cleaner from being overloaded.

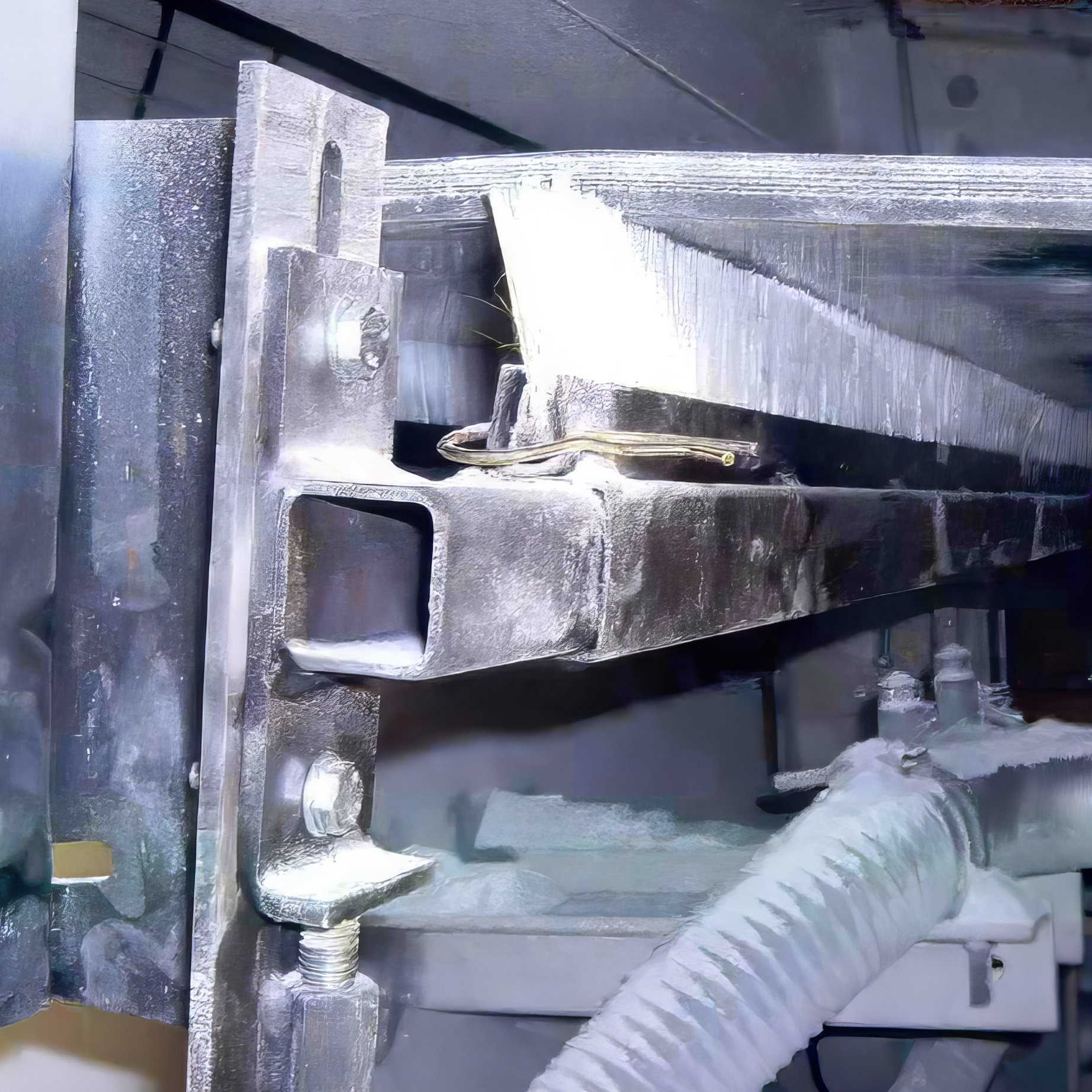

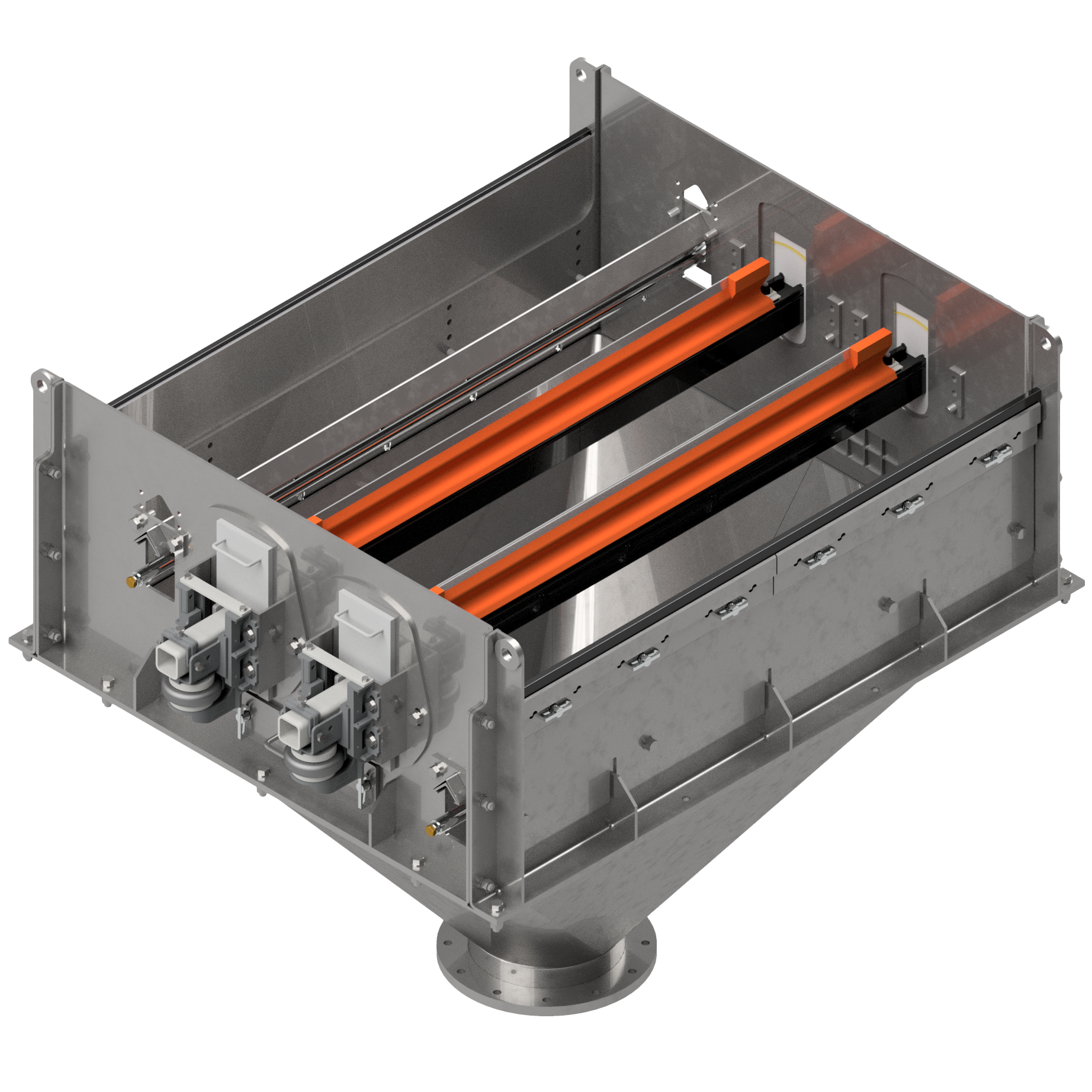

WASH STATION

The Wash Station has been designed to direct low volume, high velocity water sprays at the conveyor to dislodge adhering materials fines from the conveyor surface.

Enquire about our secondary belt cleaners.