Carryback from conveyor belts is an everyday occurrence, resulting in reduced operation efficiency, safety, maintenance cost, and environmental contamination.

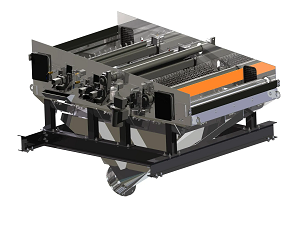

The ESS IPS Cleaners deliver superior belt cleaning performance and unparalleled serviceability for a variety of applications.

Features and Benefits

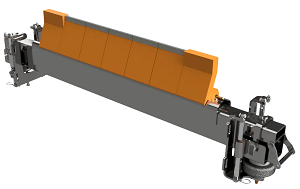

Mainframe & Cartridge

Like the ESS 20-Ten Inline Premium, the IPS Cleaner utilises a mainframe and cartridge manufactured from stainless steel, making them suitable for all environments, including sites that deal with corrosive material. The narrow profile design allows the IPS cleaner to be installed in confined spaces like restrictive head chutes. The new IPS cartridge design fully encapsulates the mainframe. This significantly reduces the material fines that can build up inside the cleaner, making the cleaner safer to service with less effort to push and pull the cartridge for blade change-out.

Tensioning Bracket

The IPS cleaner consists of a new tensioning bracket design utilising two stainless steel rods for the slide bracket to move up and down. This new design offers the benefit of creating a belt cleaner that is more reactive to belt movement while maintaining the optimal angle for efficient belt cleaning. The new IPS cleaner mount has been designed to suit the 20-Ten Inline mount bracket’s existing footprint and can be retrofitted to any existing installations.

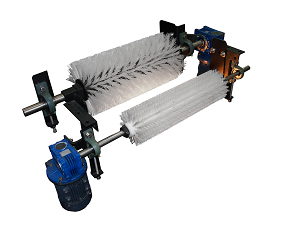

Tensioning Devices

ESS tensioning devices allow blade adjustment while the conveyor is still running from outside the chute, fine-tuning the applied pressure without stopping production.

The Tensioning devices maintain blade-to-belt pressure throughout the blade's life with minimal adjustment. It provides optimal cleaning performance while preserving blade wear rates and removing material that would otherwise pass between the belt and the blade surface.

The IPS cleaner can offer two tensioning units: spring and air. The IPS Spring tensioner unit has been designed to be interchangeable with the IPS Air Tensioner, offering client flexibility in changing tensioning units if their needs change.

Blades

ESS' modular blades allow for optimal blade-to-belt contact, with quick and straightforward blade change-out. It minimises site downtime and reduces manual handling risks during installation and maintenance.

In some cases blade, change-out can occur while the belt is still running.

ESS IPS Secondary Cleaners offer a variety of modular blades that can be changed to suit the surface conditions throughout the belt's entire life. For example, ABR Tool Steel blades for general purpose, tungsten carbide for very abrasive materials and, highspeed belts and urethane blades for damaged belts and special applications.

Related Products

Contact our team to enquire more about our belt cleaners