Designed to minimise carryback by scraping material off the belt at the discharge point.

The DT Primary Cleaner System utilises high strength urethanes, proven in industrial environments, to provide corrosion free, non-stick surfaces. These materials, combined with minimum pressure blade design create a uniquely efficient, ultimately serviceable cleaner.

Features and Benefits

Blade Types

The modular blade design is expertly engineered to increase wear life while allowing the flexibility to change blade order or material easily. The Constant Angle Radial Pressure (CARP) blade profile ensures consistent, even blade-to-belt contact, translating to highly effective and protective cleaning. We offer a variety of urethane types to match the belt profile and conditions, ensuring the perfect fit for your needs.

Our patented 'Keysafe' feature allows for blade removal from outside the chute, blade by blade, eliminating any risk potential from manual handling or confined space issues during servicing. This reduces maintenance time and minimises valuable downtime.

The urethane blade material is the ultimate safeguard for your belt surface and splices, protecting them from damage.

Our design allows the blades to fold back and pull through seamlessly without causing any harm to the conveyor belt surface or splices if the belt reverses or experiences rollback. This means you can rest easy knowing there's minimal risk of conveyor belt damage or replacement and subsequent downtime needed for repair or replacement.

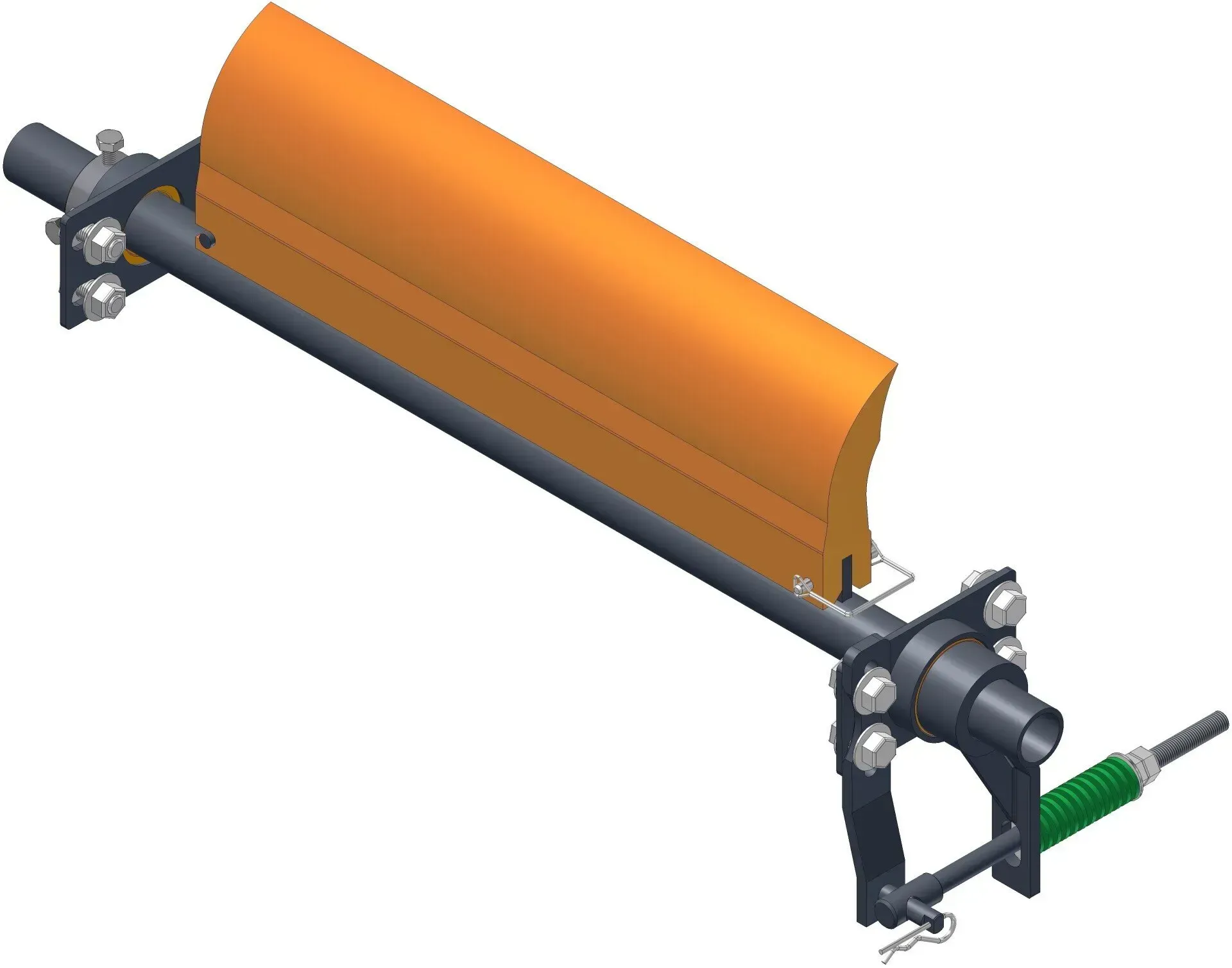

Mainframe

It is available in either mild steel or stainless steel constructions for the mainframe, which makes it suitable for corrosive environments. Thanks to its telescoping feature, the mainframe can be adjusted to fit into chutes where the conveyor belt is not centred. This feature also allows the entire track to be easily removed for maintenance. The DT Primary Cleaner has a lightweight track made of UHMW Polyethylene that resists corrosion, abrasion, and material buildup. Only the non-stick surfaces are exposed to the conveyed material. Additionally, the track is available in aluminium and fabricated mild or stainless steel.

Tensioning Devices

Different types of tensioning devices can be used to ensure that the blade remains in contact with the belt and maintains optimal cleaning performance throughout its lifespan. This helps to reduce blade wear and prevent material from passing between the belt and the blade surface. Different types of tensioning devices are available and can be customized to suit the needs of each plant. The ESS tensioning devices allow for blade adjustment while the conveyor is still running from outside the chute, making it possible to fine-tune the applied pressure without interrupting production.

Related Products

Contact our team to enquire more about our primary belt cleaners