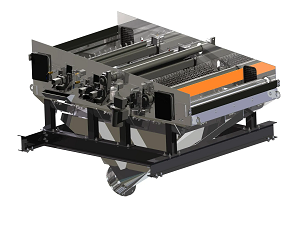

Carryback from conveyor belts is an everyday occurrence, resulting in reduced operation efficiency, reduced safety, increased maintenance cost and increased environmental contamination.

Planned maintenance shutdowns of conveyor belts are necessary to achieve effective and continual bulk handling operations. However, while conveyor areas are down production time is lost, so it is important to safely and quickly perform blade change outs to assure optimum cleaning efficiency.

Features and Benefits

Effective and Durable

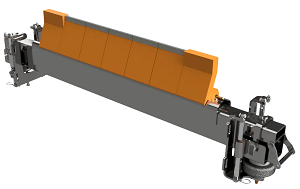

Blade options are ABR tool steel or tungsten tips for the toughest of applications. Urethane blades for damaged belts and FRAS urethane blades for underground coal applications.

Simple Mounts

The blade design incorporates the ability of state-of-the-art Urethane compounds to guarantee optimum blade-to-belt contact, utilising a simple jacking screw arrangement.

Cushions Splice Shock

The INLINE Urethane blade base flexes to absorb impact and take up any irregularities in the belt.

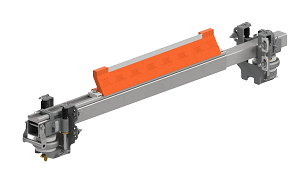

Installs in Small Chutes

The narrow profile of the ESS In-Line mainframe and blade assembly means that the cleaner can be located in even the most restricted head chutes. Change out while the belt is in operation is achievable due to the cartridge-style arrangement that can be replaced outside the chute. The blades do not contact the moving belt until the cartridge is installed.

Service is Simple

Blade to Belt tensioning while the belt is operating. By removing the locking screw and lifting the mainframe and blade cartridge clear of the belt, the blades slide out of the cartridge for service or replacement.

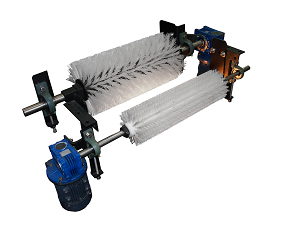

Related Products

Contact our team to enquire more about our belt cleaners