Problems with fugitive material; such as spillage and dust from conveyor load zones causes reduced operating efficiency, decreased plant safety, increased conveyor maintenance and environmental contamination.

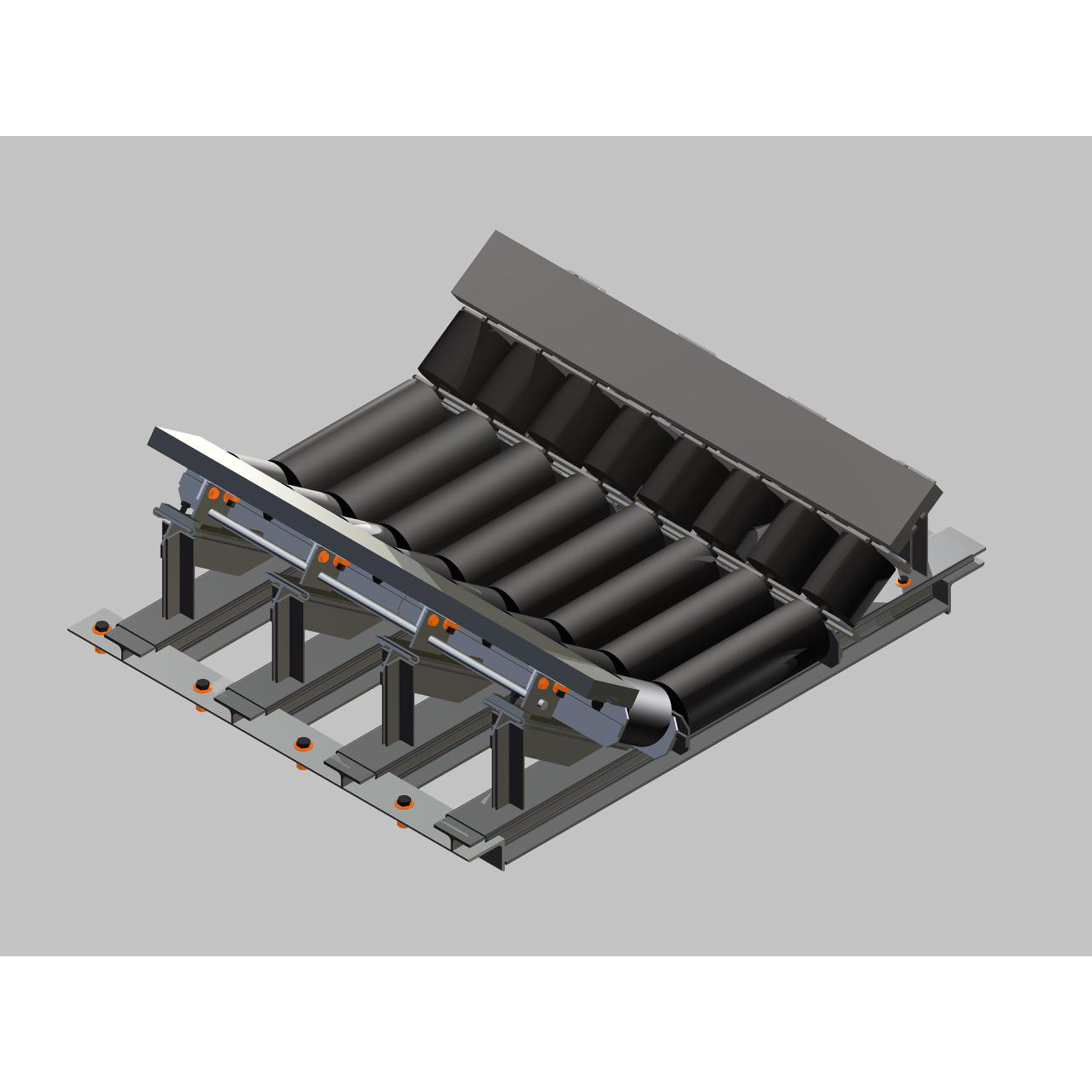

At transfer points that experience heavy impact from large lump materials, ESS GAB Impact Cradles minimise impact damage to the conveyor belt while eliminating belt sag. Skirting effectiveness is increased resulting in reduced transfer point spillage and dust emissions.

Features and Benefits

Reduced Belt Damage

ESS GAB Impact Bars extend the life of the conveyor. The shock absorbing capacity eliminates the crushing damage to the belt, idlers and conveyor structure, which is associated with loading heavy materials from a high drop point.

Reduced Belt Sag

ESS GAB Impact Bars provide a stable support at transfer points, reducing belt sag between idlers. Skirting works more efficiently, and so dust and spillage are reduced or eliminated.

Reduced drag

The polyethylene surface has extreme wear resistance for long life and low friction, with virtually no additional drag, so drive energy requirements are minimised.

Improved Risk Management

Design considerations have included the need to reduce risk to personnel servicing or installing equipment. Each bar and wing slide can be removed by a single person reducing manual handling hazards.

Reduced Maintenance Time & Cost

ESS GAB Impact Bars require virtually no maintenance and have a long operating life. Using a track-mounted system, impact bars can be inspected or changed in minutes by simply sliding out the old bar and inserting the new one.

Simple retrofit

ESS GAB Impact Cradles are individually designed and manufactured to suit each application. This means that the cradle is customised to the client’s specifications. Further adjustment is available for the outer wings.

How does it work

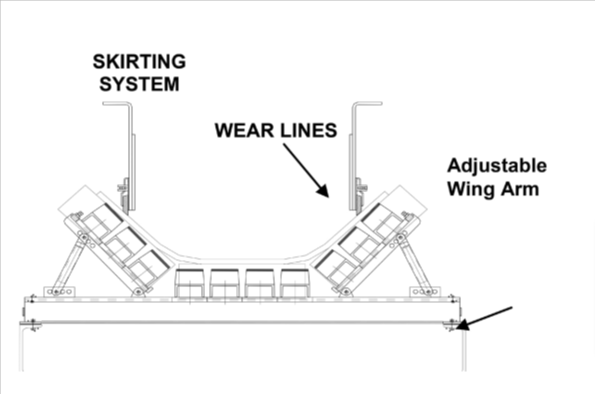

To achieve good belt sealing, the outer most bars (which carry no material load) need to be adjusted up to be in constant light contact with the belt (level with the outer idlers) to provide a flat belt under the skirting.

Because of fabrication tolerances in both idler frames and cradles, and to allow for bar wear, it is essential that some form of fine adjustment be available for these outer wing bars.

To achieve the best results and life from the bars, the centre bars should be located about 20mm below the unladen belt line. When the heavy load is applied, the belt is intermittently forced down against the bars. This intermittent contact allows air to keep the bars cool, avoiding accelerated wear (impact bars will actually last much longer under heavy lump loading than under constant fines loading).

Related Products

ESS Roller Cradles

These units retain all the advantages of an impact cradle regarding serviceability but may be used in any area where the conveyor belt load zone demonstrates high speed, and high throughput but no impact. Because the idlers are closely spaced belt sag is reduced providing a stable seal but can be serviced or replaced easily.

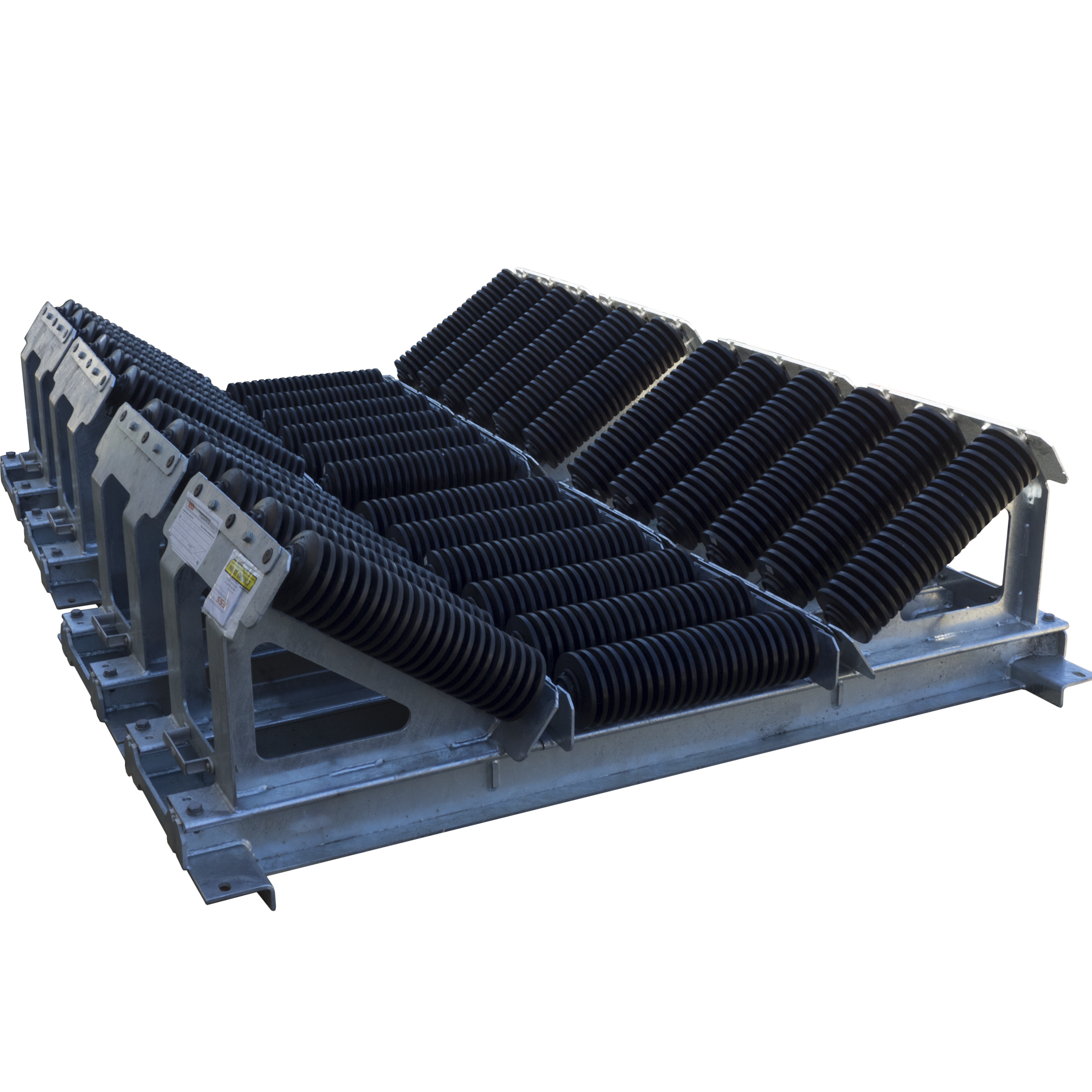

ESS Combi Cradles

For constant heavy loading without impact, ESS has developed the COMBI-CRADLE, featuring impact rollers in the centre and impact bars on the wings. The rollers are mounted in a sliding base, which allows very close roller spacing, but with the ability to replace rollers in minutes.