Every Wash Station is designed to satisfy each application’s requirements and may include stabilising idlers, sprays, squeegees and a system of belt cleaners and waster and recovery.

Some conveyor applications require a completely clean belt. Couple this with increased production demands, resulting in increased speeds, loads and fugitive material. Increases in fugitive material quickly become a hazard to the environment, employees, and production and maintenance.

The ESS Wash Station Belt Cleaning systems are designed for applications where the conveyor must be very clean.

Every Wash Station is designed to satisfy each application’s requirements and may include stabilising idlers, sprays, squeegees and a system of belt cleaners and waster and recovery. The ongoing success of any belt washing system depends on the serviceability of the hardware, including the belt cleaners, sprays and rollers.

Features and Benefits

Easily Serviced

The ESS Wash Station Incorporates the ESS conveyor cleaner and ESS Spray Bars, which are easily serviced, making for quick and effective maintenance. This means ongoing production with reduced manual handling.

Custom Design

Each Wash Station is tailored to fit each specific application and dimension of a conveyor belt, modelled in 3d and verified using FEA; the Wash Station will meet and survive the most arduous of applications. Spray systems with cleaners can be fitted in existing chutes or as stand-alone units located close to normal transfer points.

Filter Arrangement

The Filter Arrangement allows for flushing of the filter at the installation location, for easy cleaning.

Removes and Settles Fines

The ESS Wash Station system acts as a catchment for the residual fines that were not removed by the belt cleaners, settling loose fines.

Easily Evaluated

The performance of the Wash Station can be evaluated through observation, or with a Carry Back Gauge. The ESS ICT Gauge (developed in conjunction with Tundra and MECO) in the latest design for safe and repeatable sampling.

-

How does it work?

The Wash Station has been designed to direct low-volume, high-velocity water sprays at the conveyor to dislodge adhering materials fines from the conveyor surface. The water and residual fines are then removed from the belt and captured within a 316 stainless steel reservoir. The water/fines slurry is then directed via a drain pipe to a capture point for pumping back to shore for disposal or reclaim. The reservoir, or Wash Station shell, has been designed with an integrated exterior tundish and has multiple functions.

The reservoir, or Wash Station shell, has been designed with an integrated exterior tundish and has multiple functions.

- The tundish allows the opening of the Wash Station to be much larger than a standard pipe drain, to assist with prevention of blockages.

The Wash Station comprises the following components:

- Wash Station Shell

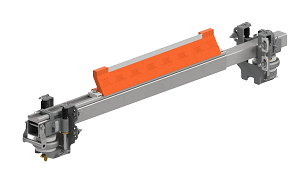

- ESS Belt Washing Spray Bars x 2

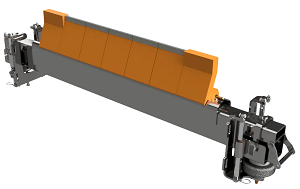

- ESS InLine Premium Secondary Cleaner x 3

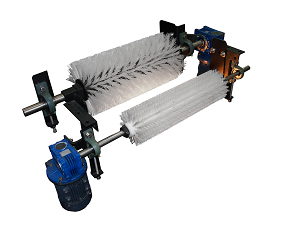

- Belt Cleaning Rollers x 2

- Wash Station Flushing Sprays

-

Backup and support

At ESS, our main priority is to offer high-quality products that meet the requirements of our clients. We are committed to fulfilling our promises and guaranteeing 100% satisfaction. Our products are proudly made in Australia, and we have sales and service teams available in most major mining centres. Our experienced service technicians can assist with installation, inspections, servicing, and troubleshooting. Additionally, our proficient design team can customize solutions to meet your plant's unique needs.

Related Products

Contact our team to enquire more about our belt cleaners

Quick Links

Contact Information

Certifications

AS/NZS ISO 9001:2015

Safety, AS/NZ 4801:2001

ICS Registered No 946/97 & 06/2982