Designed to be the most effective and economical belt cleaner available on the market today.

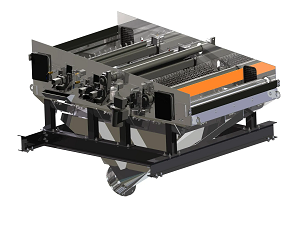

Carryback from conveyor belts is an everyday occurrence, resulting in reduced operation efficiency, safety, maintenance costs, and environmental contamination. Planned maintenance shutdowns of conveyor belts are necessary for effective and continual bulk handling operations. However, while conveyor areas are down, production time is lost, so it is important to safely and quickly perform blade change-outs to ensure optimum cleaning efficiency.

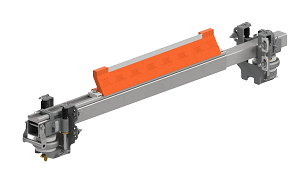

The DH Secondary Belt Cleaner effectively removes conveyor belt carryback. The DH Secondary Cleaners’ innovative design and use of industrial polymers combine to create an efficient and easily serviceable belt cleaner.

Features and Benefits

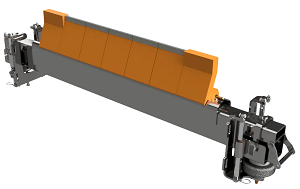

Blades

ESS offers a variety of blade materials, and the modular blade units accommodate different belt widths. Compatible mounting dimension among the ESS secondary cleaners allows for an easy upgrade to a premium ESS cleaning system for future cleaning requirements.

Rugged Polyurethane gently absorbs shock from mechanical splices and damaged belts without destroying the cleaner or damaging the belt.

Mainframe

The mainframe is available in either mild steel or stainless steel constructions so that corrosive environments can be catered for.

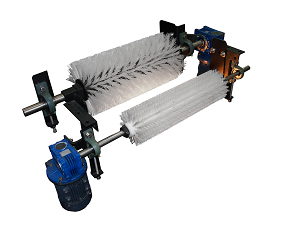

Tensioning Devices

Several tensioning devices are available to maintain the blade-to-belt pressure throughout the blade's life. This provides optimal cleaning performance while preserving blade wear rates and removing material that would otherwise pass between the belt and the blade surface.

Simple mountings mean easy installation. Use ESS frames and mountings or convert your existing hardware and labour, thus reducing initial costs.

Differing styles of tensioning devices can be customised to suit what is available at each plant. The ESS tensioning devices allow blade adjustment while the conveyor is still running from outside the chute, fine-tuning the applied pressure without stopping production.

-

How does it work?

The DH Belt Cleaner is designed to be the most effective and economical belt cleaner available on the market today. The high-strength polyurethane or injection moulded thermoplastic construction of the DH Arms ensures long life and effective cleaning under the toughest conditions. The resilient nature of these construction materials helps prevent damage to the belt cleaner itself, the belt top cover, and mechanical or vulcanised splices. Being a secondary cleaner, the DH belt cleaner is designed to be used in conjunction with an effective Primary belt cleaner. The rugged one-piece cleaning elements of the DH belt cleaner resist material build-up while absorbing the shock of splice impact. Maintenance is a simple operation. When the DH Cleaning Blades are worn to the wear line, pound out the worn blades and pound in the new.

-

Backup and support

At ESS, we proudly stand behind our products with an unbeatable 100% guarantee. Our commitment to excellence is reflected in our decision to manufacture all our products in Australia. Furthermore, we take care of our customers by maintaining local sales and service teams in most Australian mining centres. Our skilled service crews are always available for installation, service, inspection, and troubleshooting. Our expert design team is dedicated to providing tailored solutions to meet your unique plant requirements so you can trust that your ESS products are of the highest quality and reliability.

Related Products

Contact our team to enquire more about our belt cleaners

Quick Links

Contact Information

Certifications

AS/NZS ISO 9001:2015

Safety, AS/NZ 4801:2001

ICS Registered No 946/97 & 06/2982