Many applications include conveyor surfaces with cleats, ribs, groves, chevrons, or dry powder materials, which typical conveyor belt cleaners cannot clean.

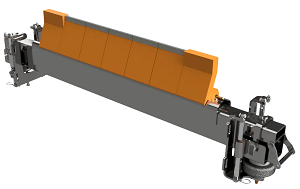

The ESS Brush Cleaner is a motorised rotary brush designed to remove adhering material from the return side of conveyor belts in conjunction with a

Primary Belt Cleaner. The ESS Brush Cleaner removes dry fibres and fines from the belt.

Features and Benefits

Segmented Brush

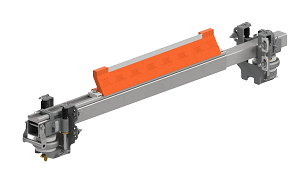

The ESS Brush Cleaner is made up of 100mm wide brush segments that slide onto the stainless steel shaft, easily accommodating all belt widths, making maintenance and replacement easy. The brush segment core is UHMW-PE. The standard brush diameter is 300 mm, but bristle length and material can be specified, allowing the brush to suit almost all applications but being most effective in dry applications. The brush rotates against the travel direction of the belt, sweeping material from the belt surface, which makes the brush cleaner and suitable for grooved, spliced, or damaged belts. The Brush Segments are easy to store and transport, reducing manual handling and risk potential.

Motor

The efficient electric motor drive is sized to provide effective operation without excessive power consumption reducing energy waste and costs.

Tensioner

The Jack Screw Tensioner maintains

brush to belt pressure with a minimal amount of maintenance.

This provides optimal cleaning performance while preserving blade wear rates and removing material that would otherwise pass between the belt and the blade surface.

Mainframe

The ESS Brush Cleaner mainframe is available in mild steel or 304-grade stainless steel, making it suitable for harsh environments. The Shaft mounted drive eliminates the need for additional brackets, making the cleaner compact and easy to install.

-

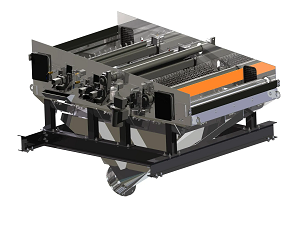

How does it work?

The ESS Brush Cleaner is a motorised rotary brush designed to be used as a cleaning device for conveyor belts. It is normally located on the return side of the conveyor belt, as close as possible to the head pulley so that material brushed from the belt is delivered into the conveyor chute.

The ESS Brush Cleaner rotates against the direction of belt travel at a speed of approximately 280 rpm. The ESS Brush Cleaner is often used as a secondary cleaner and is preceded by a primary cleaner. The ESS Brush Cleaner has 100 mm wide segments, so the same spare part can be used for all belt widths. The brush is available with a range of bristle materials and thicknesses.

-

Drive Specifications

Motor – 0.75 kW TEFC, 4 pole, 3 phase electric

motor.

Speed reduction – shaft-mounted industrial

gear reducer, 5:1 reduction ratio.

Approximate output – 280 rpm.

-

Backup and support

At ESS, we are dedicated to providing top-quality products and ensuring customer satisfaction with our 100% guarantee. Our products are made in Australia, and we have local sales and service teams in most mining centres. Our expert service crews can assist with installation, servicing, inspections, and troubleshooting. Our design team can create bespoke solutions to meet your plant's unique requirements.

Related Products

Contact our team to enquire more about our belt cleaners

Quick Links

Contact Information

Certifications

AS/NZS ISO 9001:2015

Safety, AS/NZ 4801:2001

ICS Registered No 946/97 & 06/2982