Carryback from conveyor belts is an everyday occurrence, resulting in reduced operation efficiency, reduced safety, increased maintenance costs and increased environmental contamination.

Planned maintenance shutdowns of conveyor belts are necessary to achieve effective and continual bulk handling operations. However, while conveyor areas are down production time is lost, so it is important to safely and quickly perform blade change outs to assure optimum cleaning efficiency.

The Solution

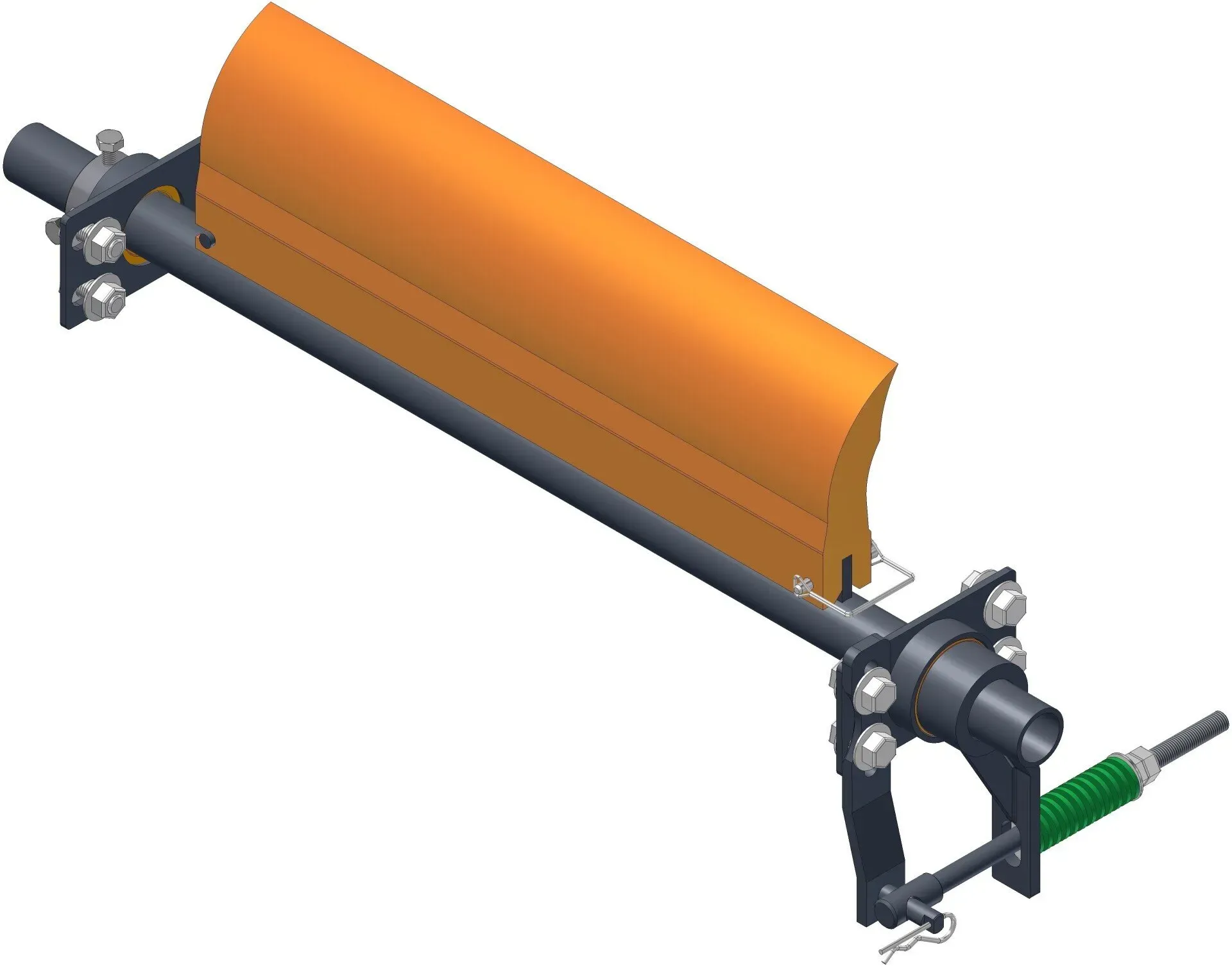

The XHD Primary Cleaner is available in a range of configurations to suit all applications. ESS representatives can recommend the best combination of options for any belt cleaning problem. ESS offers a wide variety of blade materials and a range of different widths to suit many various purposes. There are different types of tension devices to suit the job and a range of mainframe materials to suit your area and application.

Features and Benefits

Blade Types

Modular blade design provides increased wear life and ability to change blade order or material. Constant Angle, Radial Pressure (CARP) blade profile assures that there is a consistent even blade to belt contact throughout the life of the blade. This provides effective and protective cleaning. Variety of urethane types allow blades to conform to the belt profile and conditions. The Patented “Keysafe” feature allows blade removable from outside the chute blade by blade. This eliminates the risk potential from both manual handling and confines space issues while servicing the cleaners. The reduced time needed to perform maintenance means that valuable downtime can be minimised. Urethane blade material protects the belt surface and splices from damage and is designed to fold back and pull through rather than damage the conveyor belts surface or splices if the belt reverses or experiences rollback.

The risk of conveyor belt damage or replacement and subsequent downtime to repair or replace is effectively reduced.

Mainframe

The mainframe is available in either mild steel or stainless steel constructions; this means that corrosive environments can be catered for. The mainframe can be customised to suit different sized stringer lengths.

Tensioning Devices

There are several typed of tensioning device available to maintain the blade to belt pressure throughout the life of the blade. This provides optimal cleaning performance while preserving blade wear rates removing material that would otherwise pass between the belt and the blade surface.

-

How does it work?

The XHD Primary Cleaner from ESS is explicitly designed for severe applications where conventional Primary Cleaners suffer damage, high wear rates or simply can’t handle the workload. It is used on conveyor belts that have large head pulleys, wide head chutes, high speeds or handle abrasive materials.

The XHD Primary Cleaner is generally used in conjunction with at least one secondary cleaner, such as the Inline Premium Secondary Cleaner and is recommended to be used with a water spraying system. The blades are of cast urethane in a range of grades, shapes and sizes for various applications, plus a tungsten carbide tipped version for very abrasive materials.

The track mounted mainframe allows easy blade replacement from one side of the conveyor. A cleaning system can be customised to suit your application and maintenance requirements.

-

Backup and support

ESS backs up its products 100%. We proudly manufacture all our products at two separate locations in Australia. ESS maintains local stores and service crew’s in most Australian mining centres. Service crews are available for installation, service, inspection and troubleshooting. ESS design team provide a solution to your specific plant requirements.

Related Products

Contact our team to enquire more about our primary belt cleaners

Quick Links

Contact Information

Certifications

AS/NZS ISO 9001:2015

Safety, AS/NZ 4801:2001

ICS Registered No 946/97 & 06/2982