To mitigate the risks posed by conveyor belt spillage and dust at load zones, we can explore solutions that not only improve safety for personnel and the environment but also reduce cleanup costs and extend the lifespan of conveyor components.

ESS 2000 Series Lay-In skirting is a conveyor belt skirt seal designed to reduce or eliminate material spillage from conveyor belt load areas. ESS 2000 Series Lay-In skirting is suitable for use on most conveyors handling most materials. It is particularly effective however on conveyors that have poor belt support, allowing belt sag under loading, and for skirting of secondary load areas in multiple load point conveyors. Like any skirt seal system, ESS 2000 Series will perform even better when combined with good belt support and correct load chute design.

Features and Benefits

Easy to install and maintain

ESS 2000 Series Lay-In skirting features the ease of installation and maintenance associated with the entire ESS 2000 system.

Variety of clamp materials

Skirt seals are self-adjusting in service but can be further adjusted or replaced in minutes.

Multiple load points

In multiple load point conveyors, the primary load point is narrow and skirted by traditional skirt seals (ESS 2000 Series), while subsequent load points are wider and skirted with Lay-In Skirting so that the relaxed primary material load does not impact on the skirt seals.

Variety of materials

The system is available in plated mild steel or full stainless steel, and with natural rubber or FRAS rubber.

How does it work

ESS 2000 Series Lay In skirting is a conveyor belt skirt seal designed to reduce or eliminate material spillage from conveyor belt load areas.

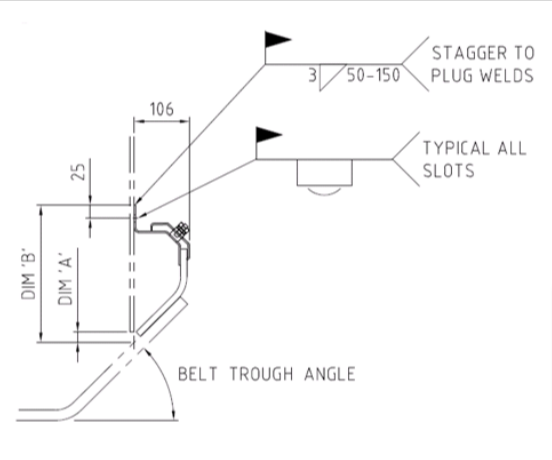

ESS 2000 Series Lay-In conveyor belt skirting is a further development of the highly successful ESS 2000 Series skirting system. The ESS 2000 Series Lay-In system comprises a rubber seal and steel clamping assembly.

The ESS 2000 Series Lay-In Skirt seal is attached to the outside of the conveyor chute or skirt plates. The offset shape of the Lay-In Skirt bracket clamps the rubber seal at a set distance off the chute wall, allowing the rubber seal to simply lay on the freeboard area of the conveyor. This results in a large area of skirt contact that self-adjusts as the rubber seal wears.

The 1200mm long mount bracket sections simply weld or bolt to the chute wall. The rubber skirt seal is held against the mounting bracket by 600mm long clamp plates which are secured by easy to use captive wedges. BACK UP AND SUPPORT ESS backs up its products 100%. We proudly manufacture all our products at two separate locations in Australia. ESS maintains local stores and service crew’s in most Australian mining centres. Service crews are available for installation, service, inspection and troubleshooting. ESS design team provide a solution to your specific plant requirements.

ESS 2000 Series Lay-In Skirting is suitable for use on most conveyors handling most materials. It is particularly effective however on conveyors that have poor belt support allowing belt sag under loading, and for skirting of secondary load areas in multiple load point conveyors. Like any skirt seal system, ESS 2000 Series will perform even better when combined with good belt support and correct load chute design.

In multiple load point conveyors, the primary load point is narrow and skirted by traditional skirt seals (ESS 2000 Series), while subsequent load points are wider and skirted with Lay-In Skirting so that the relaxed primary material load does not impact on the skirt seals/

Backup and Support

At ESS, we believe in providing the best service possible to our customers. That's why we offer a 100% guarantee on all our products. We take pride in manufacturing all our products at two separate locations in Australia. Our service teams are always available to help you with installation, inspection, troubleshooting, and maintenance. Our talented design team is dedicated to creating custom solutions that meet the unique needs of your plant.

Contact our team to enquire more about our products and services.

Quick Links

Contact Information

Certifications

AS/NZS ISO 9001:2015

Safety, AS/NZ 4801:2001

ICS Registered No 946/97 & 06/2982