High production demands increase spillage and dust at belt load zones, posing risks to personnel and the environment, and leading to higher cleanup costs and premature replacement of conveyor components.

The ESS 2000 Skirting System can be used on almost any conveyor belt load zone with excellent results. When used with effective belt support and correctly designed chute and load skirts, ESS 2000 Series skirting will virtually eliminate material loss from the conveyor load zone.

Features and Benefits

Easy to install

The ESS 2000 Series back plate is aligned and stitch welded to the existing chute wall. No marking out or measuring is required.

Low profile

The ESS 2000 Series skirting Suitable for heavy duty applications. The 16 mm thick rubber seal resists very high material loading forces without the need for heavy and unmanageable hardware.

HARSH ENVIRONMENTS

ESS 2000 Series skirting has no threaded fasteners, and when supplied in optional stainless the system is suitable for corrosive environments.

Easily handled

The 1200mm long sections are easily pallet stacked for storage and easily handled by one person at site installation time.

Ease of maintenance

The captive wedge system allows easy clamping and release of the skirt seal, while the access slots in the clamp plate allow adjustment without the need to remove any part of the system.

Longer seal life

The low height rubber can be easily adjusted to overcome uneven wear, thereby remaining usable for longer.

How does it work

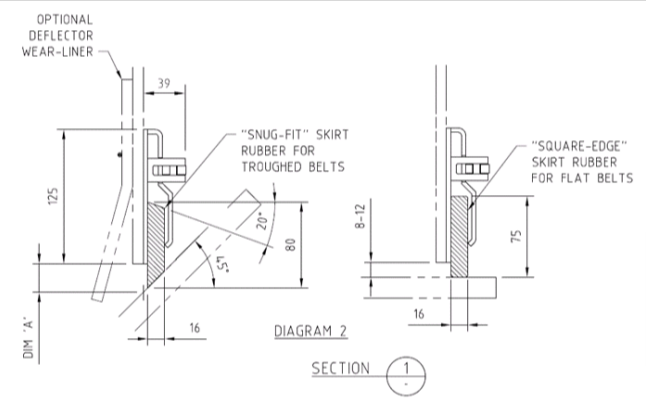

ESS 2000 Series is a conveyor belt skirting and sealing system comprising a rubber or urethane seal and a weld-on clamp assembly.

ESS 2000 Series attaches to the outside of the conveyor belt load skirts to provide an effective seal and prevent material loss and dust emissions.

Each ESS 2000 Skirting assembly comprises a 1200mm long backplate with four captive wedge or cotter assemblies and two 590mm long clamp plates. The backplate may be site cut to 600mm long and used with a single clamp plate. This enables skirt lengths of any multiple of 600mm to be accommodated using standard components.

For skirt lengths that are not a multiple of 600mm, refer to Section 4.1 for installation details. The rubber seal is secured in place by the clamp plates which are in turn held by two captive wedges (or Cotters). This system allows ease of adjustment or replacement of the rubber seal.

The addition of the urethane ESS DUAL Seal assists in the control of very dusty material.

Backup and Support

At ESS, we take pride in our commitment to 100% product satisfaction. Our products are manufactured in two locations across Australia, and we have local sales centres and service crews in most mining centres throughout the country. These crews can assist with installation, service, inspection, and troubleshooting as needed. Additionally, our design team is always ready to work with you to create customized solutions that meet the specific needs of your plant.

Contact our team to enquire more about our products and services.

Quick Links

Contact Information

Certifications

AS/NZS ISO 9001:2015

Safety, AS/NZ 4801:2001

ICS Registered No 946/97 & 06/2982