When a conveyor belt is not properly supported, spillage will occur at the transfer point. Gaps between the belt and skirting system develop, allowing fines and dust to escape. This fugitive material increases the risk of hazards not only to personnel but to the environment, conveyor components such as idlers, bearings and the belt when the material becomes entrapped in pinch points.

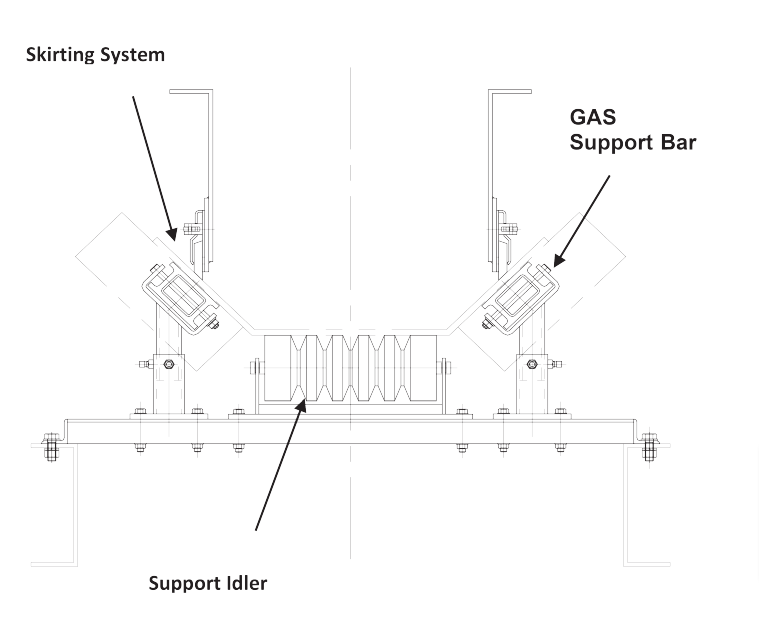

In low impact loading zones, the GAS Sealing Support System controls belt sag, reducing the spillage that causes component damage, personnel and environmental hazards. The financial result is reduced clean-up and maintenance expense.

Features and Benefits

Low coefficient of friction

The low coefficient of friction between a GAS Sealing Support System Bar and a moving conveyor belt means installation can be completed without requiring an increase in the power of the conveyor drive.

Adjustable

The GAS Sealing Support System is supplied with an adjustable mounting frame that fits any application and any belt troughing angle.

Custom Lengths

The bars come in standard 1200mm sections, although customisation to individual site specifics is available.

Increased wear life

GAS Sealing Support System Bars are designed in a unique ‘H’ configuration, which allows the use of both the top and bottom surfaces. When the top side is worn, turn the bar over and reinstall, providing double the wear life.

UHMW

Manufactured from rugged Ultra High Molecular Weight (UHMW) Polyethylene, GAS Sealing Support System Bars provide self-lubricating surface for the belt to skim over without heat build-up or undue wear on the surface of the belt or bar.

How does it work

Installed as side rails underneath the belt, GAS Sealing Support System Bars maintain a stable, sag-free belt, even in the face of strenuous loading.

The GAS Sealing Support System should be installed between idlers underneath the loading point as far down the conveyor line as is required to stabilise the belt. In loading zones with high levels of materials impact, the GAS Sealing Support System should be installed downstream from an energy-absorbing ESS GAB Impact Cradle, to provide maximum belt stability. Carry Idlers in the centre of structure can be incorporated for Heavy Duty Applications that do not require an ESS GAB Impact Cradle.

Backup and Support

ESS stands behind all its products with a 100% guarantee. We take pride in manufacturing all our products at two locations in Australia. ESS has local stores and service crews in most of the Australian mining centres. Our service crews are available for installation, service, inspection, and troubleshooting. ESS design team offers a customized solution that caters to your plant's specific requirements.

Contact our team to enquire more about our impact beds and cradles.

Quick Links

Contact Information

Certifications

AS/NZS ISO 9001:2015

Safety, AS/NZ 4801:2001

ICS Registered No 946/97 & 06/2982