Carryback Mitigation

Particles and moisture create an adhesive mixture that clings to the belt and can cause causes mistracking and blockages in head chutes. ESS have a solution for that.

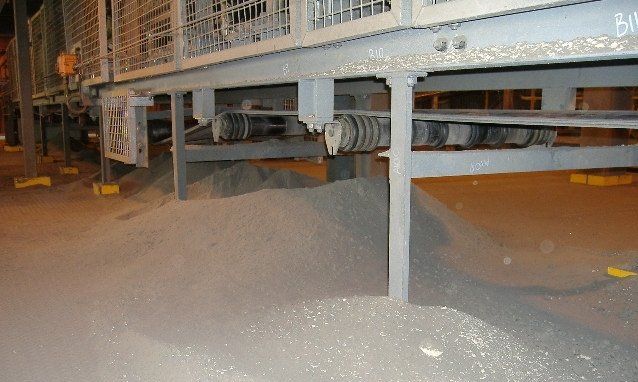

Carryback is material that adheres to the belt beyond the discharge point of the head pulley, accounting for most of the fugitive material present in conveyor systems. Material fines become dislodged along the return run of the conveyor and build-up beneath the belt. Carryback particles are typically less than 10mm in size. Particles that make up carryback typically have a higher moisture content than the overall conveyed material. As the belt rolls over the idlers the belt vibrates creating a setting action. The smallest moisture rich fines sift to the bottom of the pile, where they can create an adhesive mixture that clings to the belt.

Carryback

Risks & Concerns

Fugitive material on walkways and underneath conveyor belts represent an increased risk to personal safety including slips, trips and falls, pinch points and manual handling.

Environmentally, there is an increased risk of conveyed materials falling outside the designated areas. This in turn increases dust. Which can be harmful, depending on the sensitivity in the surrounding environment (particularly around ship loading and associated stockpiling and feeders).

Carryback build-up on rolling components causes mistracking and blockages in head chutes, which in turn leads to spillage and off-centre loading. It also reduces efficiency, increases maintenance costs, reduces plant safety, reduces product quality, shortens belt life, and leads to premature component failure. Fugitive material may bury idlers, conveyor components, or structural supports, requiring expensive clean-up labour and replacement parts.

Planned maintenance and shutdowns of conveyor belts are necessary to achieve effective and continual bulk handling operations. Installing a belt cleaner, or belt cleaning system, reduces carryback by removing the fines from the belt after the discharge point.

Properly installed, designed and maintained belt cleaning systems remove carryback and return it to the main material flow. Typically, belt cleaners are installed at or near the discharge point to remove residual fines.

Schedule Site Audit

An efficient audit of a mine's conveyor system can decrease operational costs, maintenance activities and hazard risks. The right solutions can lead to increased productivity and efficiency. We are here to help you identify areas that require improvement and provide practical solutions.

Carryback Solutions

When it comes to carry back, there are different types of belt cleaning tools available, including primary cleaners, secondary cleaners, spray bars, and wash boxes.

ESS R&D Innovations

-

Primary Belt CleanersESS Primary Belt Cleaners List Item 1

Primary Belt Cleaners or Scrapers are designed to scrape material off the conveyor belt. Positioned at the head pulley, these cleaners remove the majority of material adhered to the belt surface, thereby reducing wear and tear, minimizing the risk of belt misalignment, and increasing operational efficiency.

-

Secondary Belt CleanersESS Secondary Belt Cleaners List Item 2

Secondary belt cleaners are designed to remove residual material that remains after the primary cleaning process. They are installed behind the drive pulley and ensure that excess debris does not adhere to the belt and cause issues like belt misalignment, increased wear, and operational inefficiency.

-

Return Belt CleanersESS Return Belt Cleaners List Item 3

Return belt conveyor cleaners are specialised devices used to clean the return side of a conveyor belt. In a typical conveyor system, material is carried on the upper "carrying" side of the belt to its destination, and the empty belt then returns to the starting point to complete the loop.

-

Spray BarsESS Spray Bars List Item 4

ESS Offers a range of bespoke spray and dust suppression systems, which can also be used in conjunction ESS Belt Cleaning Solutions to create a tailored solution to customers dust suppression needs.

Call us today on 1800 074 446 for more details about our products and services.

Quick Links

Contact Information

Certifications

AS/NZS ISO 9001:2015

Safety, AS/NZ 4801:2001

ICS Registered No 946/97 & 06/2982